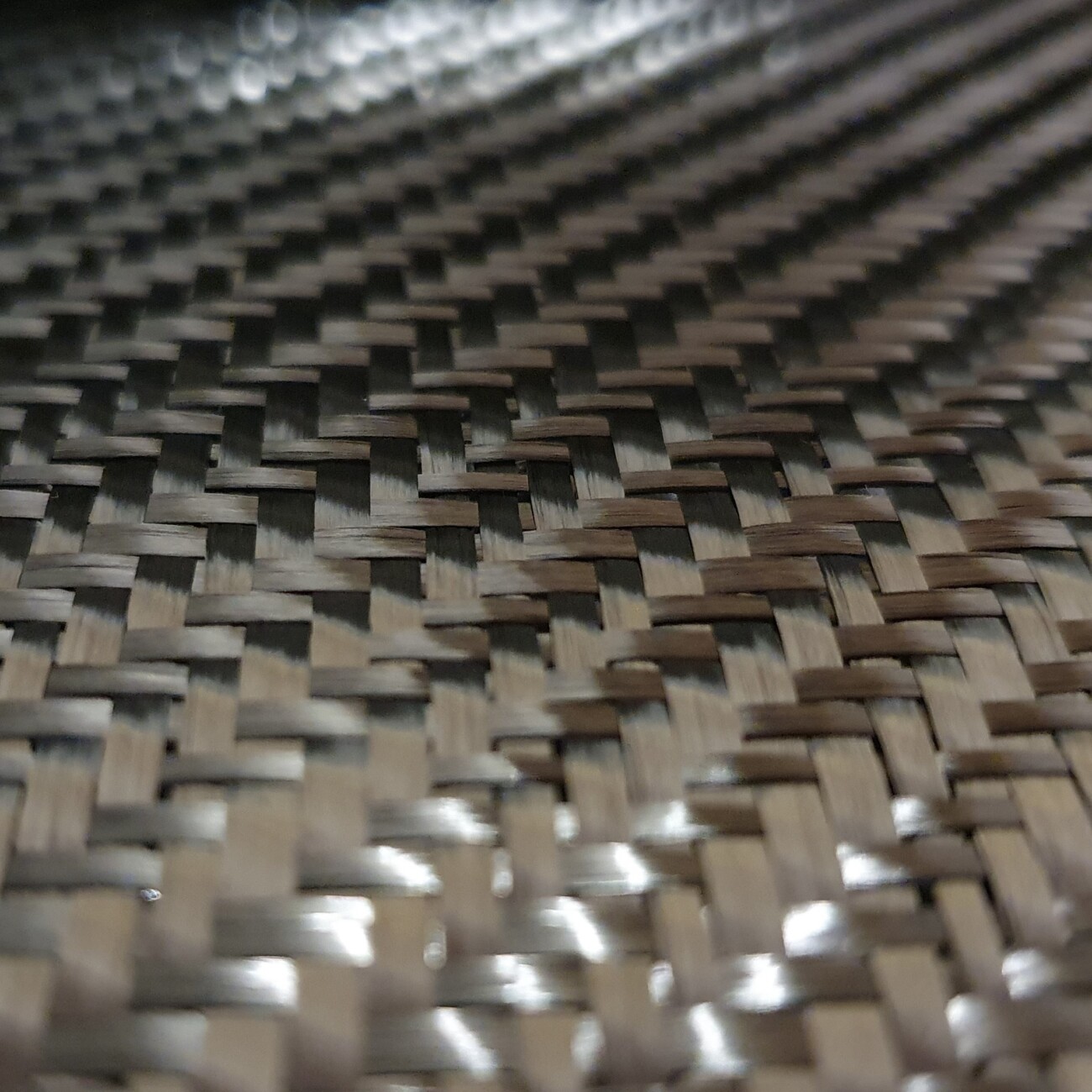

Various stabilising technologies have been present in the composites market for a long time, commonly through applying binder or powder coating. We have developed the next generation of stabilising technology using thermoplastic webs. This finish is based on calendared web technology. The use of lightweight surface webs (typically 5g – 15g) are applied to the surface of the fabric using a calendaring process providing a highly stable yet drapable fabric. The result is a fabric perfect for cutting and shaping without fraying or any significant weight increase.

The Benefits

- Prevention of fraying

- Improvement in handling

- Excellent uniformity of web distribution

- Very good drapability of fabric after stabilisation

- Full chemical compatibility with most common resin systems

- Stability of fibres after cutting

- Ability to produce pre-forms by heating the thermoplastic web

- Significantly improved impact resistance properties to the laminate

- Excellent health and safety benefits when compared to powder coating fibres

- No significant increase in aerial weight